Low temperature and low humidity dehumidification cabinet

Gezhi low temperature and low humidity dehumidification cabinet combined with ultra-low dehumidification technology, low temperature baking, fully meet the environmental requirements of 40 degrees Celsius plus 5% RH. This model is specially designed for the requirements of J-STD-033, and is suitable for PCB packaging factories. The used MSD parts are stored in low humidity and baked at low humidity and low temperature before packaging, which greatly improves the packaging yield.

The low temperature and low humidity dehumidifier has 6 main features:

1.1 To stimulate internal moisture:Combined with the dual characteristics of baking and dehumidification, the surface of the electronic parts and the deep water molecules in the interior are completely excited to make them completely dry. The water molecules in the air are completely absorbed and discharged out of the cabinet, and the dryness can reach below 5% RH. Not only can it completely avoid the potential thermal damage and easy oxidation of electronic parts when baking in a traditional 125 degree Celsius oven, but also solve the problem of cooling Afterwards, the problem of moisture attaching to the parts again.

1.2 Solve the "false drying" problem:Many defective parts often come from "false drying", that is, when the external environment is low temperature, although the surface of the electronic parts is completely dry, the deep water molecules inside the parts have not been removed and cannot be detected by instruments. When the parts are welded on-line After that, the deep water molecules in the interior are heated and expanded, which will cause the phenomenon of bursting and empty welding. This problem can be completely solved by using this machine.

1.3 Double-layer cabinet:The insulation design of the cabinet can achieve a good thermal insulation effect and prevent temperature loss. The temperature is evenly distributed throughout the cabinet, saving energy and quickly dehydrating to achieve drying effect, and quickly restore the floor life.

1.4 Temperature and humidity reading function:Directly connect the computer to the Rj45 port on the machine to record temperature and humidity data. It is not only convenient for users to monitor temperature and humidity changes, control the use of the machine, but also judge whether the machine is working normally. This function provides users with temperature and humidity data. It replaces the manual recording method in the past, and can consult and trace historical data at any time.

1.5 Temperature and humidity central monitoring system:It can monitor multiple devices dynamically and in real time at the same time, with the functions of data\/curve real-time display, recording, recall and alarm, etc. The temperature and humidity record data can be converted into Excel format and output and printed.

1.6 Alarm function:There are warning lights and alarms in the cabinet. The upper limit and delay value of temperature and humidity can be set individually. When the temperature and humidity in the cabinet exceed the upper limit, this model will start immediately or delay for a period of time according to the set value. Activate warning lights or sirens.

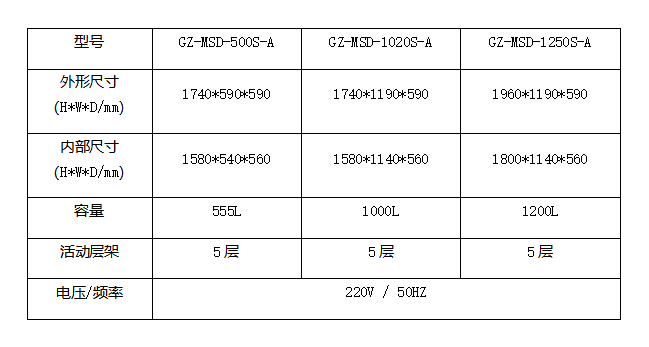

2. Specifications

Recommended Products

Send Inquiry

![[[FullTitleProduct]]](/Content/File_Img/S_Product/2022-07-20/202207201505435510.jpg)