Stainless Steel Nitrogen Cabinet

Gezhi stainless steel nitrogen cabinet control system is a new generation of microcomputer sensor to automatically control nitrogen filling, gas flow pressure is adjustable, quickly flush nitrogen into the cabinet, make the pressure in the cabinet slightly higher than the ambient gas pressure, maintain sufficient nitrogen concentration, better Drying and anti-oxidation in the control cabinet. Fully intelligent, accurate and fast to provide a low-oxygen and low-humidity environment, which can realize nitrogen protection and anti-oxidation storage in a highly clean state, for LEDs, ICs, liquid crystals, crystal oscillators, PCBs, optical electronic components, chemical The storage of pharmaceuticals, high-precision measuring devices and other industrial manufacturing provides a reliable guarantee against moisture and oxidation.

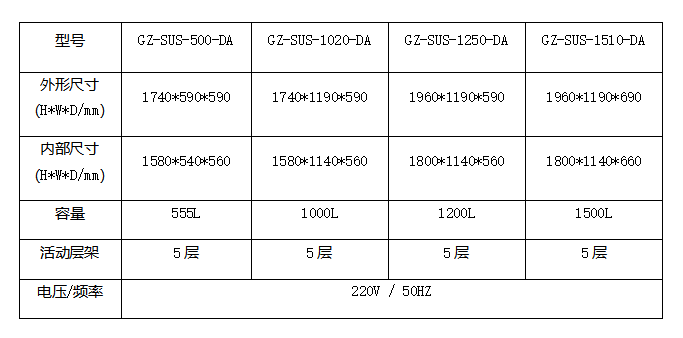

▲Product parameters

▲Features of stainless steel nitrogen cabinet

1,1.2mm stainless steel cabinet, brushed surface, high-strength cabinet, splicing fully sealed to ensure low humidity effect.

2. Adopt imported high-precision temperature and humidity sensor, precise control and easy operation.

3. Multi-point distribution of nitrogen gas supply, using an automatic program-controlled induction system to control the nitrogen intake with humidity. When the humidity reaches the set value, the system will automatically cut off the nitrogen supply, and when the set value is exceeded, the system will intelligently open the nitrogen supply , Intelligent nitrogen filling and efficient nitrogen saving.

4. The nitrogen cabinet can be expanded into a physical plus nitrogen moisture-proof combination cabinet, and the independent automatic nitrogen filling system can be set and converted according to the needs of moisture-proof or anti-oxidation working modes.

5. It can quickly dehumidify to below 5% RH, and it only takes about 5-10 minutes to recover from opening and closing the door, which is suitable for frequent opening and closing occasions.

6. It can realize the networking of multiple nitrogen cabinets. Through the networking system, the temperature and humidity of multiple moisture-proof cabinets can be monitored at the same time, and the temperature and humidity changes in each cabinet can be accurately grasped.

7. The control system is designed to run uninterrupted 24 hours a day for many years to ensure the control accuracy of the product and the overall stable operation of the equipment.

▲Application range

It mainly stores various forms of integrated circuits (ICs) such as monolithic, large-scale integrated circuits (LSI), very large-scale integrated circuits and BGA packages, etc. To prevent the PCB board from being delaminated by moisture, and to prevent SMD moisture-sensitive components from being affected by moisture during the welding process In the SMT production line, it is used for the storage of MSD devices and the storage of intermediate products in all industries that require anti-oxidative storage of unfinished products and materials in a dust-free environment. It is especially suitable for use in different levels of dust-free workshops. All users who have high requirements for material oxidation protection, such as military industry, scientific research institutes, LED manufacturing, integrated circuit manufacturing, liquid crystal panel manufacturing, high-end placement, etc.

Recommended Products

Send Inquiry

![[[FullTitleProduct]]](/Content/File_Img/S_Product/2022-07-20/202207201735139851.jpg)